Our Fields of Competence

We specialize in the most demanding graphite and CFC applications. We consider ourselves to be creators of ideas, development partners and suppliers for the most diverse companies and industries.

We specialize in the most demanding graphite and CFC applications. We consider ourselves to be creators of ideas, development partners and suppliers for the most diverse companies and industries.

We work with

- Graphite

- CFC

- Carbon Graphite

- Graphite Foil

- Coated Graphites & CFC

Our high-quality solutions are based on graphite production from planning all the way to processing by a single company. They are as versatile and forward-looking as our customers themselves.

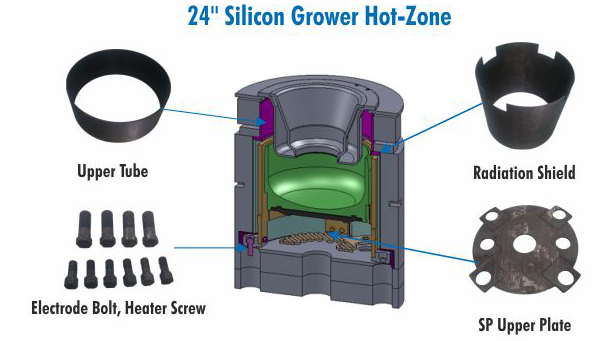

Particularly in the specialized field of high temperature applications, our long-term and economic CFC and graphite developments support new production approaches and improved quality.

Fields of Application

- Continuous high-temperature facilities

- Vacuum furnaces

- High-temperature soldering

- Sintering

- Special products

Design, Construction, Realization

Competent Initial Consultation

Thanks to our long-term experience in the design, production and processing of graphites and CFC we are able to advise our customers in a comprehensive and foresighted manner. It all starts with an initial conversation to work out the precise tasks and an analysis of optimization potential.

Well-Coordinated Design Phase

Right from the development phase we use computer-aided strength calculations aimed at providing cost and material optimization. By doing so, we can process nearly all common CAD formats (2D: DXF, DWG; 3D: Solid-

Works, STEP, IGES). Our long-term intensive cooperation with renowned research institutes helps us to find new approaches and optimize existing ones consistently.

Computer-Optimized Evaluation

Finished constructions are subjected to standardized evaluation methods with integrated collision tests. This enables us to detect and eliminate potential problems before making prototypes and saves costs and precious time. Moreover, tested constructions can be realized with maximum reliability.

Assured Production

Since we only use quality Japanese grade graphite, we can guarantee constant graphite and CFC qualities to our customers. Our leading-edge manufacturing plants provide manifold application options for CNC-controlled processing methods even including our own high-temperature furnace.

Why Us

- Collaboration with top Korean & Japanese Brands

- Major Material & Standard Size always in Stock

- 24×7 Support System

- Premium Quality with Competitive Price

- Custom Specific Requirement Can be Made

We specialize in the most demanding graphite and CFC applications. We consider ourselves to be creators of ideas, development partners and suppliers for the most diverse companies and industries.

We specialize in the most demanding graphite and CFC applications. We consider ourselves to be creators of ideas, development partners and suppliers for the most diverse companies and industries.